Pneumatics uses air to transfer energy

1. What is air?

| Gas | Volume % | Weight % |

| nitrogen | 78,08 | 75,51 |

| oxygen | 20,95 | 23,01 |

| carbon dioxide | 0,03 | 0,04 |

| hydrogen | 0,01 | 0,001 |

| argon | 0,93 | 1,286 |

| helium | 0,0005 | 0,00007 |

| neon | 0,0018 | 0,0012 |

| crypton | 0,0001 | 0,0003 |

| xenon | 0,0000 | 0,00004 |

Additionally: dust & vapour

2. Average content of dust in air

| region | average concentration (mg/m3) | widespread particle-size (mm) | biggest particle (mm) |

| country | |||

| - while raining | 0,05 | 0,80 | 4,00 |

| - while dryness | 0,15 | 2,00 | 25,00 |

| big city | |||

| - residential area | 0,40 | 7,00 | 60,00 |

| - industrial area | 0,75 | 20,00 | 100,00 |

| industrial area | |||

| - workshop | 1 to 10 | > 60,00 | >1000,00 |

| - foundry | 50 to 100 | ||

| - cement factory | 100 to 200 | ||

| - smoke stack | 1000 to 15000 |

3. Dust in industrial districts

| field of dimension (mm) | average dimension (mm) | pieces per m2 (x 1000) | part of weight (%) |

| 0 to 0,5 | 0,25 | 910000 | 1 |

| 0,5 to 1 | 0,75 | 67000 | 2 |

| 1 to 3 | 2,00 | 10700 | 6 |

| 3 to 5 | 4,00 | 2500 | 11 |

| 5 to 10 | 7,50 | 1750 | 52 |

| 10 to 30 | 20,00 | 50 | 28 |

4. Equipment to be considered in the generation and preparation of compressed air

Þ Air compressorÞ Air reservoir

Þ Air filter

Þ Air dryer

Þ Air lubricator

Þ Pressure regulator

Þ Drainage points

Þ Oil separators

Note: The location of compressor influences to a greater or lesser degree the amount of contamination

Types of main contamination in compressed air

Þ solids (dust)Þ water

Þ oil

Interaction of contaminants

Þ dust combine with water or oil to form lager particlesÞ water combines with oil to form emulsions

| Compressed air should be properly prepared to prevent malfunction |

Results of poorly-prepared air:

Þ pipework contamination and damage: flow-rate decreases, rust of iron, oxidation of copperÞ valves and machinery damage: rapid wear of seals and moving parts

Þ contamination of silencer: Reduced flow through control valve, slowing down of actuators

Þ icing of valves: expanded air is cooling down - moisture freezes

Þ moisture precipitates: corrosion and wash out or initial grease, may hardening seals

Þ oiled-up valves: oil blocks bore for pilot air, switching function is impaired causes valve malfunction, may cause seal swelling, contamination of process e.g. food industry, paint spraying,

5. Drying of air

The atmospheric air taken in by the compressor always contains a proportion of moistureThe higher the air temperature, the greater the quantity of water vapour which can be take up by the air.

If the saturation point of 100% is reached, the water is precipitated in the form of droplets

How much water can be carried by air?

| °C | g/m3 | °C | g/m3 |

| 1 | 5,15 | 26 | 24,38 |

| 2 | 5,52 | 27 | 25,78 |

| 3 | 5,92 | 28 | 27,22 |

| 4 | 6,35 | 29 | 28,77 |

| 5 | 6,80 | 30 | 30,36 |

| 6 | 7,28 | 31 | 32,02 |

| 7 | 7,77 | 32 | 33,78 |

| 8 | 8,29 | 33 | 35,64 |

| 9 | 8,84 | 34 | 37,57 |

| 10 | 9,40 | 35 | 39,60 |

| 11 | 9,99 | 36 | 41,72 |

| 12 | 10,65 | 37 | 43,91 |

| 13 | 11,35 | 38 | 46,20 |

| 14 | 12,07 | 39 | 48,62 |

| 15 | 12,82 | 40 | 51,14 |

| 16 | 13,63 | 41 | 53,76 |

| 17 | 14,48 | 42 | 56,49 |

| 18 | 15,37 | 43 | 59,35 |

| 19 | 16,32 | 44 | 62,34 |

| 20 | 17,29 | 45 | 65,44 |

| 21 | 18,31 | 46 | 68,63 |

| 22 | 19,38 | 47 | 71,92 |

| 23 | 20,53 | 48 | 75,40 |

| 24 | 21,74 | 49 | 79,08 |

| 25 | 23,04 | 50 | 82,98 |

Compressing the air means reduction in volume, compressed air cannot carry as much water as atmospheric air!

|

Example:

1. Compressor is working at 20 °C and delivers 10 m3/h, air humidity is 50%amount of water in the air per hour: 100% saturation at 20 °C: 17,3 g/m3

m = 0.5 x 17,3 g/m3 x 10 m3/h = 86,5 g/h

2. Compressor is compressing the air at an absolute pressure of 7 bar and the temperature of the air rises to 40 °C.

Volume of the air: V = 10 m3/h / 7 = 1.43 m3/h

100% saturation at 40 °C: 51,14 g/m3

amount of water in the compressed air per hour: m = 51,14 g/m3 x 1,43 m3/h = 73,1 g/h

3. Precipitated amount of condensate entering the pneumatic system

m = 86,5 g/h - 73,13 g/h = 13,4 g/h

4. Air cools down on the way to the machinery, Temperature inside the plant 20 °C:

100% saturation at 20 °C: 17,29 g/m3

maximum amount of water in the compressed air at 20 °C:

m = 17,29 g/m3 x 1,43 m3/h = 24,7 g/h

precipitated amount of condensate: m = 73,1 g/h - 24,7 g/h = 48,4 g/h

Example

1. Compressor 10 m3/h, at 40 °C, 85% humidityAmount of water in air: m = ?

2. Absolute pressure 8 bar, air temperature rises to 80 °C

Maximum amount of water in compressed air: m = ?

3. Air cools down on 20 °C

Amount of water in compressed air: m = ?

Amount of precipitated water: m = ?

6. Three different methods for drying air:

|

dew point temperature about + 2 °C

|

dew point temperature up to - 90 °C

|

dew point temperature up to - 40 °C

The lower the temperature dew point the more water will be reduced from the air

7. Description of different systems:

7.1 Low temperature drying

|

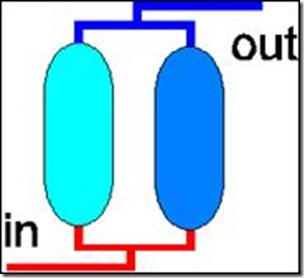

7.2 Adsorption drying

|

Then the air gets into drying chamber 1. By outlet point C a small part of dry air (about 15-20%) as taken to dry chamber 2.(Cold regeneration). In chamber 1 vapour is taken by an granulate.

This can be:

- molecular sieve Na AlO2 SiO2 (used by FESTO-dryer)

- active aluminium oxide Al2O3

- silica gel SiO2

When the switching valve B changes the ports from chamber 1 to chamber 2 the volume from chamber 1 goes quickly out over an air-silencer. 90% of the humidity goes to the surrounding area. Rest of 10% humidity is dried by dry air.

Regenerating time about 2 minutes.

7.3 Membrane drying

|

8. Filtering of air

available types:| Filter element | Filter size (mm) | Residual oil in air (mg/m3) |

| Sinter cartridge | 40 | - |

| Sinter cartridge | 5 | - |

| Micro filter | 1 | < 0,5 |

| Fine filter | 0,01 | < 0,01 |

| Charcoal filter | 0,003 | < 0,003 |

Function of service unit with sinter or micro filter element:

The compressed air passes through a baffle plate in the filter bowl. The air is rotated, and the heavier dust particles and water droplets are spun by centrifugal force against the inner wall of the filter bowl and run down the wall of the housing. The air which has been precleaned then passes through the filter element.Function of service unit with charcoal filter element:

The filter element consists out of a highly porous charcoal element. The charcoal itself has a enormous effective surface. Even gaseous air contaminants like oil vapour and fumes are absorbed within by the charcoal.9. Quality classes of compressed air

| Class | Particle size mm | Particle density mg/m3 | pressure dew point °C | maximal oil content mg/m3 |

| 1 | 0.1 | 0.1 | -70 | 0.01 |

| 2 | 1 | 1 | -40 | 0.1 |

| 3 | 5 | 5 | -20 | 1.0 |

| 4 | 15 | 8 | +3 | 5 |

| 5 | 40 | 10 | +7 | 25 |

| 6 | not specified | not specified | +10 | not specified |

| 7 | not specified | not specified | not defined | not specified |

10. Recommended ISO-classes for some applications

| Solid | Water-Dew Point | max. Oil rate | ||||

| Application | Class | [mm] | Class | [°C] | Class | [mg/m3] |

| Mining | 5 | 40 | 7 | - | 5 | 25 |

| Cleaning | 5 | 40 | 6 | + 10 | 4 | 5 |

| Welding Machinery | 5 | 40 | 6 | + 10 | 5 | 25 |

| Tool Machinery | 5 | 40 | 4 | + 3 | 5 | 25 |

| Compressed Air Cylinder | 5 | 40 | 4 | + 3 | 5 | 25 |

| Compressed Air Valve | 3 to 5 | 5 to 40 | 4 | + 3 | 5 | 25 |

| Packing | 5 | 40 | 4 | + 3 | 3 | 1 |

| High precision pressure reg. | 3 | 5 | 4 | + 3 | 3 | 1 |

| Air for measurement | 2 | 1 | 4 | + 3 | 3 | 1 |

| Bearing air | 2 | 1 | 3 | - 20 | 3 | 1 |

| Sensors | 2 | 1 | 2 to 3 | - 40 to- 20 | 2 | 0,1 |

| Food | 2 | 1 | 4 | + 3 | 1 | 0,01 |

| Photographic processing | 1 | 0,01 to , 0,1 | 2 | - 40 | 1 | 0,01 |

The recommended max. water contend will vary with the intended use of the compressed air. For instrument air it is often stated that the pressure dew point should be 10°C below the lowest expected site temperature.

How can we reach recommended ISO-classes?

|

4.6.5

4.5.4

4.4.4

3.4.4

3.3.4

3.3.3

2.2.2

1.1.2

1.1.1

Adsorption dryer Microfilter Charcoal-Fine-filter

Overview about preparation methods

Solids:

Þ Cyclone separator, baffle-plate separators for particles > 15 mm (Filter bowl with baffle plate)Þ Sintered filters (metal or polymer) for particles > 5 mm (Sintered filters 40 mm or 5 mm)

Þ Fibre filters for particles > 1 mm (Fine filter LFMA)

Þ Micro fibre filters for particles > 0,01 mm (Micro filter LFMB)

Water:

Þ Condensation and separation (cooling of air)Þ Absorption drying (Air dryer LDF)

Þ Adsorption (membrane filters LD)

Þ Cyclone separator and filters (only for water in liquid sate, filter bowl with baffle plate)

Oil:

Þ Fibre filters for oil content > 0,5 mg/m3 (liquid or aerosol form, fine filter LFMA)Þ Micro fibre filters for oil content > 0,01 mg/m3 (micro filter LFMB)

Þ Charcoal filters for oil vapour and odours (charcoal filter LFMPX)

How do our service units fit into this?

| Type | Quality classes | ||

| Solids | Water | Oil | |

| FRC- | 5 | - | - |

| FRC-5M- | 3 | - | - |

| LFR- | 5 | - | - |

| LFR-5M- | 3 | - | - |

| LF- | 5 | - | - |

| LF-5M- | 3 | - | - |

| LFMB- | 2 | - | 4 |

| LFMA- | 1 | - | 2 |

| LFMPX- | 1 | - | 1 |

| LD- | - | 2/3 | - |

| LDF- | - | 1 | - |

Mounting of service units

Þ The flow direction of each element has to be in the same direction (observe arrows on elements )

Þ Observe the consecutive order of the elements

Þ Mounting of service unit should be as close as possible to machinery

Þ Service units have to be mounted horizontally

Þ After mounting to the machinery the service unit should be visible and easy accessible for operation