1 Fundamentals of control

1.1 The control chain

Each control system is comprised out of three discrete sections:- Output devices and their drivers

- Processing elements (store the control program)

- Input devices

The control chain is characterised by a signal flow from signal input via processing to signal output.

|

- placement of components in the circuit diagram

- identification of physical size, current or voltage rating of components

- to determine the layout of the control cabinet/console

- locating of components for maintenance and service

1.2 System structure

The components of an electropneumatic system can be identified as belonging to one of the three basic groups of a control chain.Examples for assignment of devices to the three control levels in electropneumatics:

Additionally there is a fourth group in the system structure, which is the energy supply. For the pneumatic parts the energy supply is an air compressor while for the electrical part the energy supply is presented through a generator, the mains, a battery or the power supply.

2 System Components

2.1 Power Supply

These are available in various configurations with different levels of filtering and regulation of the output voltage.

The power supply should be able to comfortably manage the total system current requirements without overloading. Consideration should be also given to the impact of future expansion of the system.

2.2 Air supply system

The air supply for a particular pneumatic application should be sufficient and of adequate quality.Aspects of consideration in preparation of air supply:

- type of compressor to be used to produce the quantity required

- storage requirements

- requirements for air filtration

- acceptable humidity levels to reduce corrosion and sticky operations

- lubrication requirements if necessary

- pressure requirements

- line sizes to meet demand

- drainage points and exhaust outlets in the distribution system

- layout of the distribution system to meet demand

Service unit

Malfunction can be considerably reduced in the system if the compressed air is correctly prepared. The air service unit is a combination of the following elements:

- air filter with water separator

- air pressure regulator

- air lubricator

3 Input Elements

3.1 PNP/NPN configuration

|  | ||

Generally two sensor designs are distinguished, PNP (positive switching) and NPN (negative switching).

PNP

In case of PNP sensors, the output is connected to the positive potential in the switched state. This means one connection of the load must be connected to the proximity sensor output and the other connection to 0V.

NPN

In case of NPN sensors, the output is connected to the negative potential (0V) in the switched state. This means one connection of the load must be connected to the proximity sensor output and the other connection to the positive potential (e.g. 24 V).

3.2 Pressure switch

A pressure switch senses the air pressure of the air-line and compares this with a pre-set adjustable value. When the pressure reaches the pre-set limit the internal changeover contacts are switched and an electrical output signal is given.

|

|

|

Pressure switches have always a hysteresis, which prevents the output signal from flickering. On some switches the hysteresis is also adjustable.

3.3 Reed switches

Reed switches are also known as magnetically actuated switches. They are commonly used to sense the position of a piston within a pneumatic cylinder. The contacts close when the switch is exposed to a magnetic field, e.g. that of a permanent magnet of a cylinder piston. |  | ||

|

Reed switches are chracterized by their small size and fast switching time. However high currents or short circuits easily destroy them. Therefore they should be never used to switch directly a solenoid valve.

3.4 Inductive sensor

Operating principle |  | ||

The most important components of an inductive proximity sensor are an oscillator, a demodulator and an amplifier with an output stage. When supply voltage to the sensor is switch on, the oscillator starts and a defined current is flowing. If an electrically conductive object is introduced into the active zone of the sensor, eddy currents are created, which draw energy from the oscillator. This leads to a change in current consumption of the oscillator. The two statuses of current consumption are electronically evaluated to create a switching in the output stage.

Inductive sensors are available in flush and non-flush fitting. Where sensors are to be flush mounted in a metal fixture, the flush-fitting type has to be selected. The non flush-fitting type requires a free-zone around the active area to avoid false switching due to the surrounding metal. However non flush-fitting sensors can be flush fitted in electrically non-conductive material like wood or plastics.

Different sensing material leads to a change of the effective switching distance. Reduction factors for different materials are listed below:

Reduction Factors for different materials

| Material | Reduction Factor |

| Mild steel | 1.0 |

| Chrome Nickel (stainless steel) | 0.7 – 0.9 |

| Brass | 0.35 – 0.5 |

| Aluminium | 0.35 – 0.5 |

| Copper | 0.25 – 0.4 |

| Object material | Metals |

| Typical nominal switching distance | 0.8 – 10 mm |

| Max switching current | 75 mA – 400 mA |

| Sensitivity to dirt | Insensitive |

| Typical switching frequency | 10 ... 5000 Hz |

| Protection class | Up to IP67 |

3.5 Capacitive Sensors

|

The operating principle is based on the measurement of the change of electrical capacitance of a capacitor in a RC resonate circuit. If an object or medium (metal, plastic, glass, wood, water) is introduced into the active zone, the capacitance of the resonant circuit is altered. This results in a change of the output stage of the sensor.

The sensitivity (switching distance) depends not only on the distance of the medium from the active surface. It also depends on the thickness and kind of medium detected. Furthermore, most capacitive sensors have a potentiometer to adjust the sensitivity. This allows suppressing the detection of certain media. For instance, it is possible to determine the fluid level of water through the wall of a bottle.

Reduction factors for different materials

| Material | Reduction Factor |

| All metals | 1.0 |

| Water | 1.0 |

| Glass | 0.3 – 0.5 |

| Plastic | 0.3 – 0.6 |

| Cardboard | 0.3 – 0.5 |

| Wood (dependent on humidity) | 0.2 – 0.7 |

| Oil | 0.1 – 0.3 |

| Object material | All materials with dielectric constant larger 1 |

| Typical nominal switching distance | 5 - 20 mm |

| Max switching current | Max. 500 mA |

| Sensitivity to dirt | sensitive |

| Typical switching frequency | Up to 300 Hz |

| Protection class | Up to IP67 |

3.6 Optical sensor

Optical sensors use red or infrared light for the detection of objects. Each type of sensor basically consists out of two main units: the emitter and the receiver. Emitter and receiver are either installed in a common housing (diffuse, retro-reflective types) or housed separately (through-beam type). The emitter LED sends a light beam, which can be diverted, focussed, interrupted or reflected. The phototransistor of the receiver accepts the light, separates external light influences and electronically evaluates the optical signal.To suppress the influence from external light sources, the light beam on an optical sensor in modulated. Red light makes it easier to adjust the sensor, since it is visible in contrast to the infrared light. On the other hand infrared light can span greater distances and is less susceptible to interference from ambient light.

Variants of optical proximity sensors

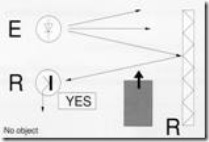

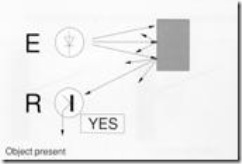

Through-beam sensors

|

Through-beam sensors consist of separately assembled emitter and receiver. To trigger the sensor output signal, the cross section of the light beam must be covered by an object. The object should permit only minimum penetration of light, but may reflect any amount of light.

|

- Large switching range possible ( up to 100m)

- Small objects can be detected (especially with fibre optic cable)

- Objects can be diffuse reflecting, mirroring or low translucent

- Good positioning accuracy

Disadvantages of through-beam sensors

- Two separate modules

- Can’t be used for completely transparent objects

Retro-reflective sensors

|

Light emitter and light receiver are installed in a single housing. An additional reflector is required. To trigger the sensor output signal an object must interrupt the light beam between sensor and reflector. This interruption must not be compensated by direct or diffuse reflection of the object. Transparent, bright or shiny objects may remain undetected.

|

- Simple installation and adjustment

- Offers larger switching range in comparison to diffuse sensors

Disadvantages of retro-reflective sensors

- Transparent, very bright or shiny objects remain undetected

Diffuse Sensors

|

|

Advantages of diffuse sensors

- No additional reflector required

- The object can be diffuse reflecting, mirroring or transparent to translucent as long as a sufficiently high percentage of the light beam is definitely reflected.

- Diffuse sensor allow frontal detection, i.e. in the direction of the light beam

Disadvantages of diffuse sensors

- Not suitable if accurate lateral response is crucial

Correction factors taken into account for different object surfaces

| Material | Factor |

| Cardboard white | 1.0 |

| Expanded polystyrene, white | 1.0 – 1.2 |

| Metal shiny | 1.2 – 2.0 |

| Wood, coarse | 0.4 – 0.8 |

| Cotton material, white | 0.5 – 0.8 |

| Cardboard, black matt | 0.1 |

| Cardboard, black shiny | 0.3 |

| PVC, grey | 0.4 – 0.8 |

3.7 Switches and relays

Switches are primarily distinguished by their contact configuration- normally open (path 3 to 4)

- normally closed (path 1 to 2)

- changeover contacts (path 1 to 2 or 1 to 4)

On actuation a normally open (NO) contact enables energy flow while a normally closed contact (NC) disables energy flow. The changeover contacts (CO) can be used as either normally open or normally closed contacts or both.

|

Contact configuration

Switches may consist of a single pair of contacts either normally open (NO) or normally closed (NC) or have a set of changeover (CO) contacts. More complex configurations (multi-pole switches) are available. A range of actuation methods is also available such as pushbutton, mechanical electrical or pneumatic actuation. The actuation method can be momentary (non-latching) or detented (latching),

Important considerations when selecting switches include

- Current and voltage rating of contacts

- Level of electrical insulation of the switch housing

- Number and configuration of contacts

- Method of actuation and switch design

Most switches including relays use a numbering system to identify their contacts. Additionally the whole switch can be identified (e.g. switch number one, two,...).

Contact numbering system

|

In electropneumatics relay are generally used as signal processors. Rather than switching a solenoid directly via a limit switch or electric sensor, the relay contacts act as a buffer, carrying the larger amount of current.

Relay characteristics

- A small amount of energy applied to the relay coil can control a larger energy flow through the relay contact

- Relays are able to switch a number of independent circuit paths

- Isolate the input signal (relay coil) from the output signal (relay contacts). This is refereed to be a potential free contact.

-

|

High operating speed, i.e. short switching times.

4 Actuating devices

4.1 Solenoid valve

Solenoid principleIf a conductor is formed into the shape of a coil and current is passing through the conductor, an electromotive force is generated. By adding turns to the conductor, the magnetic field is strengthened and adding turns to the conductor increases the force. Adding an iron core to the solenoid further increases the force.

DC solenoid

|

When current is applied to the solenoid head, a magnetic field is generated which influences the valve stem and the soft iron core at the end of the stem housing. The divers polarities at the soft iron core and the valve stem initiates a force of attraction, which causes the stem to be pulled up. When the current is switched off, the magnetic field collapses and the spring pushes back the stem into its initial position.

When the solenoid is switched on, the current rises slowly. During development of the magnetic field the inductance of the coil generates a force which opposes the applied voltage. This explains the slightly slow energising action of DC solenoid.

Switching off solenoids

When inductive devices such as solenoids are switched off, the magnetic field collapses. This can result in an induced voltage peak, which is many times higher than the normal coil voltage.

This voltage peak causes arcing across switches and relay contacts resulting in increased wear of the contact material. Electronic devices such as proximity sensors or transistor outputs o PLCs can be seriously damaged.

To protect electronic devices and to reduce the increased contact wear of switches, an arc suppression circuit is fit in parallel to the solenoid.

The use of the following elements is possible:

- Arc quencher

- Zener diode

- R-C combination

|

Illuminated seals fit between socket and solenoid and contain additionally two arc quencher diodes.

Comparison between DC and AC solenoids

| DC solenoids | AC solenoids |

| Advantages | |

| Gentle switching operation | Short switching times |

| Easily switched on | Large pulling force |

| Low turn-on power | Usually no spark suppression required |

| Low holding power | |

| Long service life | |

| Silent | |

| Disadvantages | |

| Voltage peak occurs when switched off | High mechanical stress |

| Arc suppression required | Severe temperature rise when permanently switched on |

| Long switching time | Higher current consumption |

| Buzzing noise | |

4.2

Direct actuated valve

Advantage: Short switching time for pneumatic output Disadvantage: High force needed to operate the valve stem. This would require large solenoids

4.3 Pilot operated solenoid valve

The pilot valve can be considered an amplifier. By using pilot control, the size of the solenoid can be kept to a minimum. This has two main advantages:-

|

reduced power consumption

-

|

reduced heat generation

Single/double solenoid valves

Unlike valves with a spring return the double solenoid valve remains in its last switching position, even with power removed from both solenoids, until an opposing signal is applied. This means the valve has memory characteristics. For electropneumatic circuits this characteristics has several advantages:

- only short duration of electrical signal necessary to switch the valve

- demand on the electrical power supply can be minimised

- in case of electrical power loss the valve will not switch back, thus preventing uncontrolled cylinder movements

Application example for single solenoid valves

- pneumatic press

- shut of f pneumatic supply when E-stop button is pressed

- saves one output on a PLC controller compared to double solenoid valve

Application example for double solenoid valve

- clamping of workpiece during processing

- shorter overall switching time (spring return is 40ms compared to 15ms with solenoid)

- applications where energy saving or reduced heat generation is important

4.4 Pneumatic cylinder

|

If a cylinder moves large masses, cushioning is used in the end positions. Before reaching the end position, a cushioning piston interrupts the direct flow of air to the outside. The air is forced to flow through flow control valve. Therefore the speed of the piston is slowed down for the last part of the stroke to reduce impact on the cylinder.

Other features

· Pneumatic end position damping is adjustable via two regular screws.

· The Piston of the cylinder can be fitted with a permanent magnet which can be used to operate a proximity switch for position sensing

· Cylinder barrel is usually made from seamless drawn steel tubing and can be coated to withstand harsh environments.

· Piston rod is preferably made form heat-treated, rust-proofed type of steel.

· The two caps are fastened to the cylinder barrel by tie rods

· The seals are made from either Perbunan (up to +80 °C), Viton (up to +190°C) or Teflon (up

to +200 °C)

Rotary actuator

|

5 Electropneumatic symbols

Symbols should identify and clearly represent the following characteristics of components:- function

- labelling of connections

- actuation methods

- number of switching positions

- simplified representation of flow/current path

Symbols do not represent

- construction method or manufacturer

- component dimension or energy handling capability

- orientation of valve/cylinder ports or electrical connection

- physical details of element

5.1 Most important electrical symbols:

5.2 Most important pneumatic symbols for electropneumatic

6 System Development

Each electropneumatic circuit can be divided in two distinctive parts- pneumatics

- electrical

There exists an interface between the pneumatic and electrical elements. These elements will appear on both the pneumatic and electrical circuit diagrams.

The steps in development of a basic circuit

- Describe operation of circuit

- Develop a displacement step diagram for the pneumatic actuators

- Draw the pneumatic circuit

- Specify the pneumatic/electric interface

- Draw the electrical diagram

- Document maintenance information (numbering and designation of elements)

- Document type of components and technical data

Development guide for pneumatics

- circuit layout should follow the signal flow through the control chain from bottom to top

- cylinders and directional control valves are drawn horizontally with the cylinders operating from left to right.

|

Numbering of pneumatic circuit elements is done the following way

| Cylinder | 1.0 | 2.0 | 3.0 |

| Final Control Element | 1.1 | 2.1 | 3.1 |

| Input Element even numbering for extracting* | 1.2 | 2.2 | 3.2 |

| odd numbering for retracting* | 1.3 | 2.3 | 3.3 |

| *Internal Festo designation, not according to VDI 3226 |

- layout should follow the signal flow through the control chain (input, processing, output) from top to bottom

- circuits with relay control can be further divided into a control section and a power section

- components should be placed from left to right according to the sequence of operation

Example for electrical layout

Electrical circuit elements are numbered, following the direction of signal flow from top to bottom and from left to right. Often elements are also given the number of the rung in which they appear as well as the number of the page on which they are drawn.

Electrical elements in the circuit drawing are illustrated in the initial position. If a switch is operated (e.g. limit switch) it is drawn in operation (NO drawn as NC and NC drawn as NO) which is afterwards indicated by an arrow

|  | ||

Example of actuated proximity sensor and limit switch

6.1 Link between pneumatics and electric layouts