Manufacturing of Plastic Bottles (PET)

Introduction to PET Bottles

Plastic Bottles nowadays is something that is in high demand, is it mainly because of its durability. Majority of people around the world use it in a daily basis. Containing innumerous uses, plastic bottles or plastic to be specific, must be one of the greatest discoveries in the recent centuries.

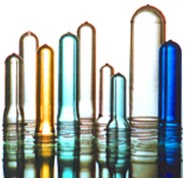

Fig01: Polyethylene terephthalate, otherwise known as PET, is the most

commonly used plastic nowadays

add by Top Ten Innovations

About Polyethylene terephthalate used for Bottling

Polyethylene terephthalate is not made is not made in a single process. It is made by the reaction of two chemicals known as Purified terephthalic acid (PAT) and ethylene glycol (EG).

These two chemicals form Polyethylene terephthalate along with other types of plastic, used in variety of applications such as engineering, nylon production, etc.

Below are some Properties of Polyethylene terephthalate

- Density: 1.38~1.40g/mm3

- Melting Temperature: 254-256°C

- Crystallinity: >=45%

PET is a long chained molecule with the repeating unit displayed above, resin, a bluish white substance, is made from poly condensation of terephthalic acid and ethylene glycol. Resin manufacturers supply PET in the form of small pellets, each weigh about 0.05 grams.Being transparent, PET can reach a tensile strength of about 1/3~1/2 of steel's.

The number of PET repeating units per chain, used in the bottle industry to make plastic bottles is about 100 to 155, usually labeled in terms of resin IV.

Uses of Polyethylene terephthalate

Also known as PET, is a thermoplastic is which is one of the types of plastic amongst million others. By far the most useful type of plastic, PET bottles are used mostly in the beverage industry, where the bottles are filled with the particular beverage and supplied around the globe. It can be water, fresh juice, or any other beverage. Some of the most common uses would be bottling of mineral water, edible oil, juice, cosmetics, pharmaceutical, etc.

Main Advantages of PET

- Pure – PET does not involve, by reacting with the food or beverage which is kept within the container. Therefore, PET complies with international food contact regulations.

- Lightweight – 10 times, lighter than a glass pack, PET bottles, hence, reduces shipping costs by 30%. If a glass and PET bottle having the same size is compared in volume it can store, PET will come in first, as its wall is thinner.

- Crystal Clear – The product looks clean and healthy and in physical good shape. These attract attention and increases the sales of the products contained within it.

- No Leakage – Due to the absence of a weld line in the bottom the PET bottles leakage does not occur.

- Design Flexibility – Can be designed in all shapes and sizes, designs and colors.

- Recyclable – As it is one single material, PET bottles can be washed and crushed into flakes and remolded into shape. It has other uses after it is recycled such as for strapping, making carpets, etc.

Production of PET bottles

Usually PET bottles are manufactured using 2 different methods.

These are :-

- One-Step "hot perform" method.

- Two-Step "cold perform" method.

Step-one "hot perform" method

This method is just one step, from PET granule to finished bottles, all the processors are done in one integrated machine. That is from the injection mold of the preform to the removal of the preform from the injection cavity, and to stretch blow the preform to a bottle all in one machine, while the temperature remain constantly high for the whole process as injection molding and blow molding, the material should in an elastic form. This method saves a lot of energy as the material only has to be heated only once, that is when it is injected to the cavity to produce the preform. The One-Step method is commonly used in small or medium PET production companies.

Fig03: One-Step “hot perform” method Integrated Machine.

Step-two"cold perform" method

This method has 2 distinct machines to perform the injecting and blow moldings. The preform is injected into shape on the first machine, and then the preform is reheated as the it isn't brought directly to the blow molding machine and blown on the second machine. This method is not very efficient as the heat lost is considered as a loss of energy. But this machines are fully automated.This method is used in most medium to large scale PET production companies.This machine is 200% more efficient than the one-step machine.

Fig04: Two-Step “cold perform” method, Fully automated machine.

Usually the Two-Step Method is used in production of PET bottles.

Driying and Dehumidifying of PET

PET is a type of plastic that absorbs moisture with an average water content of 0.05%. To increase the quality of the preform in transparency and physical performance the PET is dried to reduce the water content of the PET resin to less than or equal to 0.005%. The following drying methods are used.

- Oven Dry – The drying is done at a temperature of 110°C for a maximum of 8 hours after which PET will start to fail. The trays with PET inserted into the oven are about 50mm thick. The oven isn't connected to the injection machine ant the dried PET is moved manually.

- Hopper dryer– The widely used method of drying PET as it very economicaland works along with an autoloader, therefore the process is continuous and automatic.

Fig5: A hopper dryer used to dry PET granules.

- A Dehumidifier – Similar to the hopper dryer this also words together with an autoloader, but it is the most efficient method in drying. The PET dries in at a temperature of about -32°C, thereby increasing the durability and the final finish of the PET bottle.

Fig06:A Dehumidfier used to dry PET granules.

The Optimum drying temperature would be about 150~170°C. The best duration for drying the PET would be about 4 hours. The drying time should not surpass 7~8 as will deteriorate the PET.

Injection Molding of the PET Preform

Fig7: An Injection molding machine with essential equipment attached.

The above picture shows an injection molding machine with the autoloader and dryer other essential equipment needed in the process.

Fig8: Schematic illustration of the injection molding process.

The process is simple, the heated PET which is in the molten form is injected into the injection chamber (2),by the rotation of screw barrel (1) within the machine, until the chamber is full.

Once the chamber is full, the screw pushed forward (3) to fill the injection cavity with molten plastic through the nozzle into the mold.

The temperature within the injection molding machine are different, at the rear end of the machine the temperature should be around 275°C, at the middle of the machine about 282°C, at the nozzle about 280°C. And at the runner the temperature should be around 270°C for the bottle formed to have optimum specifications. (These temperature may vary a little depending on the design of the mold)

Fig9: PET Preform Mold

Fig10: Preform being Heated

Subsequently the molten plastic within the mold,called the preform, should be cooled. The cooling water used to cool the perform should be in the temperature range between 15~20°C, the pressure also has to be controlled, therefore a water chiller is used. The pressure should be kept around 500,000 Pa or 5Bar.

The PET preform is ejected (4) from the mold. Now the preformis reheated to the temperature until it is suitable for the blowing process.

Fig11: A Typical Water Chiller.PET Preforms

Fig12:PET Preforms

Stretch Blow Molding of the PET Preform to Container

The Following process in production of PET is a type of Blow molding called Stretch Blow molding, as air is blown into the preheated PET Preform.

The other types of Blow molding are:-

- Extrusion Blow molding

Fig13: Extrusion Blow molding Process.

2. Injection Blow molding

Blow molding is a process of forming hollow object by blowing a blowing into thermoplastic, in this case PET Preform, which is heated and in its maximum elastic condition. The blow molding process used in production of PET Bottles is Stretch Blow Molding.

This process is also called Biaxial orientation blow molding as the preform is first stretched by the blowing device, for the reason that the molecules of the preheated preform is aligned in one direction and all parallel to each other, then blown in right-angles to the direction of the molecules being aligned.

The theory behind the how this works is, when the PET is heated the long-chained molecules can loosen then as an alternative to breaking, they orient when stretching. Therefore,this (stretch blowing)is also called biaxial orientation as it deals with two axes stretching.

This stretching increases the strength of the material because instead of the molecules in the material act separately, they act as one whole unit.

The following characteristics are improved or increased as a result of this stretching the PET Preform before blowing into it.

- Tensile Strength

- Impact Strength

- Barrier

- Chemical Resistance

The ideal temperature for orientation for PET is 105°C.

The compressed air () blown into the PET Preform is first cleanedthrough an air purifier (). The air must be cleaned since air contaings moisture and oil, which will directly affect the quality of the bottle. The PET preform is mounted on to the blowing machine (). After purifying, the air is blown into the preheated PET preform using a blower on to the mold ().

The thickness of the Stetched blown bottels are 0.25~0.38mm. This thickness is suffiecient as the orientation will increase the products' quality.

Possible Defects while production of PET Bottles

One of the Major defects in the production of PET Bottles is the production of Acetaldehyde.

This compound also called as AA, is the taste of an acidic taste in most citrus fruits. This taste in the bottle can ruin the taste of the drinks, especially if its water as the taste of pure water isn't strong enough to disguise the taste of AA, unlike the sweet flavors. If the presence of the AA is noticed the quality of the product literally, goes down the drain.

AA is produced along with the PET when the temperature of the material is higher than 260°C, this temperature is reached inside the injection molding of the preforms, therefore is the process is not maintained correctly, AA is produced along with the PET preform.

Decreasing the melt temperature and the residence time and help reduce the production of AA.

Other forms of defects are briefly mentioned below.

- OH- or COOH- end groups doesn't becomes non-reactive.

- Amount of poly-functional macromolecules increases.

- Hydroxide and peroxide groups build up at the surface of the PET and etc.

Fig16:The Total PET Bottle Production Process

Manufacturing Costs

Process: PET bottles manufacturing process involves two basic stages of pre-form manufacturing and Bottle Stretch Blow Moulding. In a one-step process, the PET bottles are made directly from the resin. Both the pre-form manufacturing and stretch blow moulding is performed on a single line. (see Table-I)

Machinery | Number | Indian Rupee |

Injection Molding Machine | 1 | 750000 |

Blow Molding Machine | 2 | 800000 |

Compressor | 1 | 150000 |

Cooling Tower | 1 | 150000 |

Chiller Unit | 1 | 80000 |

Lather 8ft, refurnished | 1 | 110000 |

Lathe 5.5ft | 1 | 72000 |

Pillar Drill 26 inches with pump | 1 | 50000 |

Facer | 1 | 150000 |

Shaper | 1 | 125000 |

(These are indicative estimates, therefore, the intended investor must make his own calculations by market survey). Injection moulding machines of two different sizes are required as the proposed production mix depends upon different sizes. The usual machinery delivery time is 15-20 days, while import can take up to 4 months' time, depending upon the availability. The stretch blow moulding machines are being manufactured locally. Lathe machines, pillar drill, facer and shaper, required for the workshop, are also manufactured locally. (see Table-II)

Human Resource | Number | Annual Salary |

CEO | 1 | 360000 |

Production Manager | 1 | 192000 |

Accountant | 1 | 96000 |

Injection Machine Operators | 2 | 168000 |

| Blow Machine Operators | 2 | 168,000 |

Pre-form Handler | 1 | 30,000 |

Helpers | 4 | 120,000 |

Guards | 3 | 108,000 |

Land and building: An area of about 5,000 sq. ft would be required for the project. Management building 100, production Area 1,800, raw material store 300, finished goods store 500, loading area 700, workshop area 850, cooling tower/chiller 700 sq. ft.

Key assumptions: 288 days p.a. Annual production capacity 5,840,640 bottles, capacity utilisation (1st Year) 40 per cent, capacity growth rate (yearly) 2 per cent, maximum capacity utilisation 95 per cent, first year production utilisation 2,304,288 bottles. (see Table-III)

Others | Growth Rate |

Electricity | 10% |

Wages | 10% |

Office equipment | 10% |

Machine maintenance | 5% |

Initial approximate cost/Kg (Rs) 81, Sales Tax 15 per cent, freight cost per kg 1.22. Weighted average cost of raw material per bottle may come to Rs2.81. Other heads include administrative costs, promotional expenses, insurance, electricity and taxes. (see Table-IV)

Other | Depletion Rate |

Building & infrastructure | 5% |

Machinery & Equipment | 10% |

Furniture & Fixtures | 10% |

Project life | 10 years |

Debt: Equity Ratio | 50:50 |

Interest rate on long term debt | 16% |

Discount rate for calculation of NPV | 20% |

Raw Material Consumption per Bottle And the final costs. (see Table-V)

Size | Weight | Cost (Indian Rupees) per 100 Bottles | Cost (Sterling Pounds) per 100 Botttles |

0.5 Liter | 15.5 | 146 | 1.98 |

15 Liter | 33.3 | 313 | 4.25 |

5 Liter | 74.7 | 702 | 9.53 |

Weighted average cost of raw material per 100 bottles comes to about £3.82. While average sale price per 100 bottles may be £9.21.

(Investment Opportunities: Packaging medium.